Technical Expertise

Guangzhou Debao Electric Appliance Factory / 2015-12-01Thickness of impact: 0.4~7mm

Outer diameter and depth of deep-drawn product: 180mm and 140mm

The precision of cold stamping deep-drawn part is up to IT7, and some parts can be up to IT8.

Thickening and deep drawing

After the metal is deep drawn for times, its wall thickness will become thinner. When selecting materials, customers will reserve a thinning amount so as to ensure that the product has the sufficient wall thickness after being formed. This will increase material cost and part weight (the non-deep-drawn position is too thick). We apply thickening and deep drawing process to meet the requirement that individual position of the product is thicker than the material.

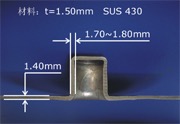

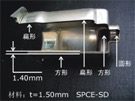

Special-shaped deep drawing

Light weight of automotive makes the part structure more compact, saving more space. Non-circular flat motor will be widely applied in actuator motor of automotive. The shape of this motor has multiple grading shifts between round and square shapes. When its dimension accuracy, form and location tolerance are ensured, there should be sufficient wall thickness. Its forming is difficult, and it is particularly difficult at square position. Customers will select thicker materials so as to make up the thinned amount. We apply our self-developed new process to overcome the shortcomings of traditional processes and reduce the deep-drawn working procedures. When thinner homemade materials are used, product precision and wall thickness are superior to the previous product which greatly reduces the manufacturing cost.

Cpk control is adopted for process capability. The Cpk rating of Debao is A+.

1.Cpk refers to process capability index which is a quantitative reaction of a project or process standard and an indicator for project evaluation.

2.When Cpk is used to control process station, cost should be considered as the primary factor. The impact of quality characteristic on back-end process should also be considered.

3.Cpk rating standard: (Corresponding countermeasures can be made for the calculated process capability index based on this standard.)

A++ Cpk≥2.0 super excellent. Consider cost reduction.

A+ .0 > Cpk ≥ 1.67 excellent. Maintain it.

A 1.67 > Cpk ≥ 1.33 good, good capability and stable state. A+ is advisably enhanced.

B 1.33 > Cpk ≥ 1.0 ordinary, ordinary state. If process factor has a slight variation, it will cause adverse danger. All kinds of resources and means should be used to enhance it to A.

C 1.0 > Cpk ≥ 0.67 weak. There are many nonconforming processes, and its capability must be enhanced.

D 0.67 > Cpk unacceptable, too weak capability. Design process should be rectified.

A++ Cpk≥2.0 super excellent. Consider cost reduction.

B 1.33 > Cpk ≥ 1.0 ordinary, ordinary state. If process factor has a slight variation, it will cause adverse danger. All kinds of resources and means should be used to enhance it to A.

Used metal types:

Hot-rolled material (Shanghai Baosteel) :

SPHC、SPHE

SAPH370、SAPH400

B550L、B510L

S45C (Nisshin Steel-Guangzhou Mitsui Company)

Cold-rolled material (Shanghai Baosteel) :

SPCC-SD、SPCD-SD、SPCE-SD

DC01、DC04

BLD、BUSD、BUFD、BSUFD

SECCN5 (20/20)、SECEN5(20/20)

DC54DZ 120/120

Stainless steel:

SUS 304-2B、SUS430-2B

SUS430-2D